YOUR CUSTOM WATERJET SOLUTION

Hoosier WaterJet: Precision Cuts in the Heart of Indiana,

Expertly Engineered for a Variety of Materials

Metal

We offer superior edge quality compared to other production cutting methods while removing expensive secondary operations required to remove HAZ or clean an edge prior to joining.

Tile and Stone

From marble to granite, ceramic tile to glass – if you can handle it without breaking it – we can cut it. We can cut shapes, inlays and custom designs for a variety of applications.

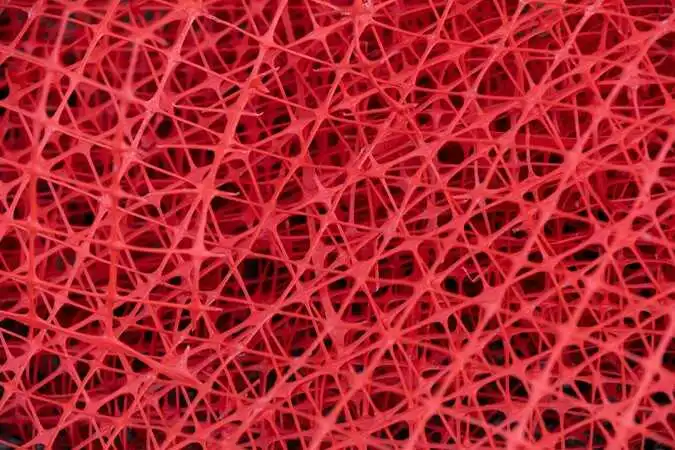

Plastic/Soft Materials

Cutting thin, soft, and/or porous materials with abrasives can result in material getting trapped, leading to an undesirable, dirty appearance. Waterjet cutting is perfect for these types of materials.

Our Dynamic Waterjet® from Flow provides an alternative to traditional techniques, particularly when materials are sensitive to high temperatures generated by these methods. Leveraging an output of 60,000 psi, we can cut almost any material - metal, stone, or composite - at up to 400% the speed of conventional flat stock waterjet cutting machines.

Metal Tolerance Tables

| Thickness | Tolerance: Non ID/Arc | Tolerance: ID/Arc |

|---|---|---|

| ≤ 0.499" | +0.005" / -0.005" | +0.010" / -0.010" |

| 0.5" to 0.999" | +0.010" / -0.010" | +0.015" / -0.015" |

| 1" to 1.999" | +0.015" / -0.015" | +0.020" / -0.020" |

| 2" to 2.999" | +0.030" / -0.030" | +0.030" / -0.030" |

| 3" to 3.5" | +0.050" / -0.050" | +0.050" / -0.050" |

Note: Lead-in and lead-out details will be discussed when placing an order.

| Thickness | Tolerance |

|---|---|

| ≤ 0.375" | +0.062"/-0" |

| 0.376" to 1.500" | +0.125"/-0" |

| 1.501" to 3.000" | +0.187"/-0" |

| ≥ 3.001" | +0.250"/-0" |

Note: Tolerances must be mutually agreed upon by the purchaser and sales representative for any material drawn into a part. Otherwise, the above standard thickness-based tolerances will be applied.

Hoosier WaterJet provides custom cutting solutions in Indiana and across the Midwest. As a division of High Performance Alloys, we've positioned ourselves as an industry leader, leveraging cutting-edge technology for precision and excellence.